MRO Support:

At Prior PLM Medical, we understand the importance and value of correctly maintaining and servicing high-performance injection moulds. Our established repair facility, with its highly experienced staff, refurbish damaged and worn production tools to perform as new.

-

Repairs Department

Prior PLM Medical’s dedicated repair facilities specialise in the repair of high-quality, high volume medical / pharma mould tools. Mould tools are received from manufacturing locations around the world and are repaired to the highest international standard, which is critical to an industry where the retention of aesthetic qualities and dimensional tolerances is of paramount importance.

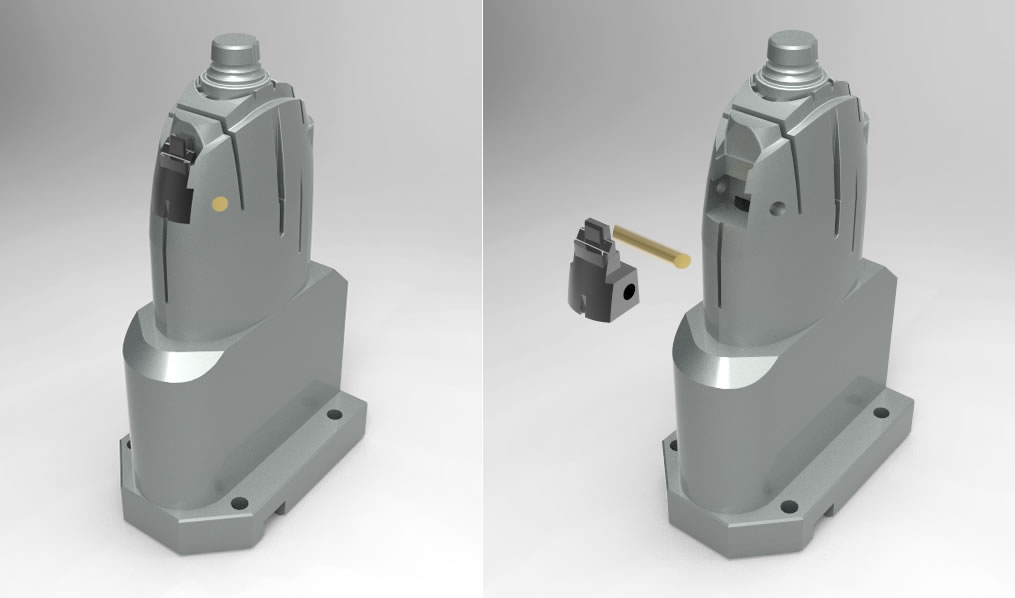

Types of repairs

- Gate wear

- Shut off damage

- Split-line damage

- Modifications

- Hot Runner systems

- Large scale overhauls

- In addition, we have recently expanded our repair facility to be capable of servicing even the largest multi-cavity moulds and their respective hot runner systems

- Gate wear

-

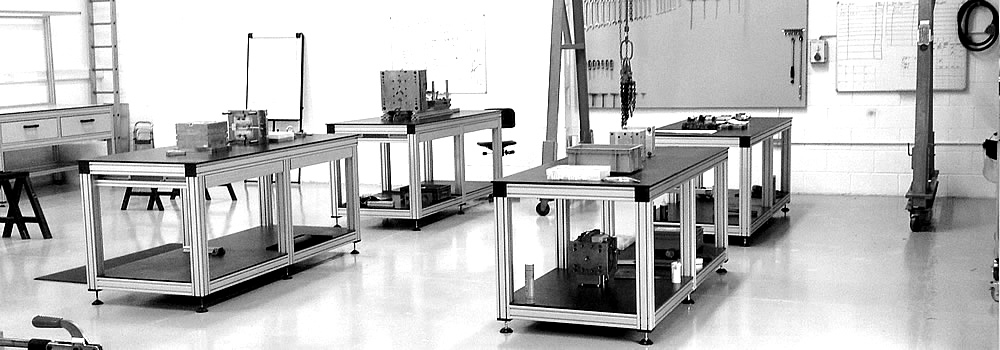

Maintenance Department

Methodical Aproach

Moulds are collected by qualified engineers only and brought back to Prior PLM Medical’s MRO Facility in Carrick-on-Shannon. All maintenance work is executed according to best practice and as described in detail in your contract. We will replace all interchangeable and worn items as deemed necessary and in strict accordance to the terms agreed in your contract.

Data Capture

Everything we do is fully documented and logged. Outstanding issues will be addressed in accordance with your prescribed maintenance programme and the tool will be re-assembled as documented.

Tool Trial

If required, tools can be trialled at our facility prior to return. This ensures that all mechanical aspects of the mould – electronics, pneumatics and water circuitry – are working perfectly. The tool is then carefully packed in an appropriate crate / container and returned to your facility within the agreed time period. All tools are accompanied by a full report of all works carried out with additional observations noted regarding the tool condition, appearance or function.

Schedule & Duration

The schedule and duration of maintenance activities are agreed with you, the customer, in advance. We guarantee strict adherence to all plans, ensuring minimal disruption to your production runs.

-

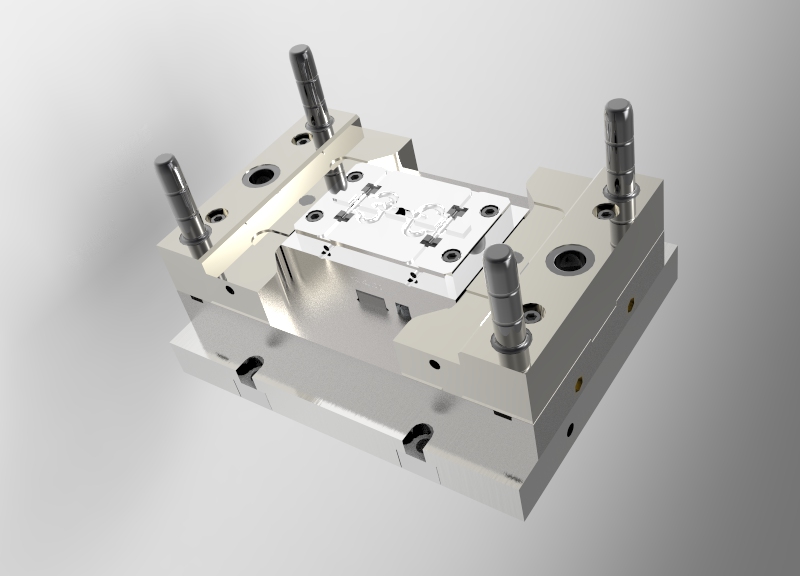

Overhaul

A costly mistake, often repeated by companies, is to view their moulds as no longer fit for use because of the damage they have sustained through wear and tear, accident, or “end of life” forecast – but need not be the case. By allowing our engineers to inspect these moulds, compile a report on their condition and the steps necessary to revitalise them, we could potentially save your company significant sums of money on replacing “spent” tooling that, with the necessary expertise, can be returned to a viable resource.

A costly mistake, often repeated by companies, is to view their moulds as no longer fit for use because of the damage they have sustained through wear and tear, accident, or “end of life” forecast – but need not be the case. By allowing our engineers to inspect these moulds, compile a report on their condition and the steps necessary to revitalise them, we could potentially save your company significant sums of money on replacing “spent” tooling that, with the necessary expertise, can be returned to a viable resource.Unique Skills

Our engineers understand that mould manufacture and mould MRO require different sets of core skills and experience. By using a methodological approach, we are capable of undertaking all types of mould maintenance and repairs, ranging from everyday gate, cavity, and split-line repair, to extensive mould overhaul and refurbishment, in an efficient, accurate and timely manner.

Lifecycle Planning

We can prove that by implementing and adhering to our strict Mould maintenance schedule, you will increase Mould yield, efficiency and life expectancy, along with consistent and improved part quality throughout the entire life-cycle of each mould.

Data Management

Our engineers use IT systems to track component & historical service data along with up-to-date records of inspections, repairs and services to create a tailored maintenance strategy for each individual mould in your facility. We understand that a well maintained mould is priceless.

Rapid Response

We have our own rapid response vehicles, which can be quickly deployed to collect your mould, regardless of its size or location, and bring it back to our specialist facility in Carrick-on-Shannon for repairs or maintenance.